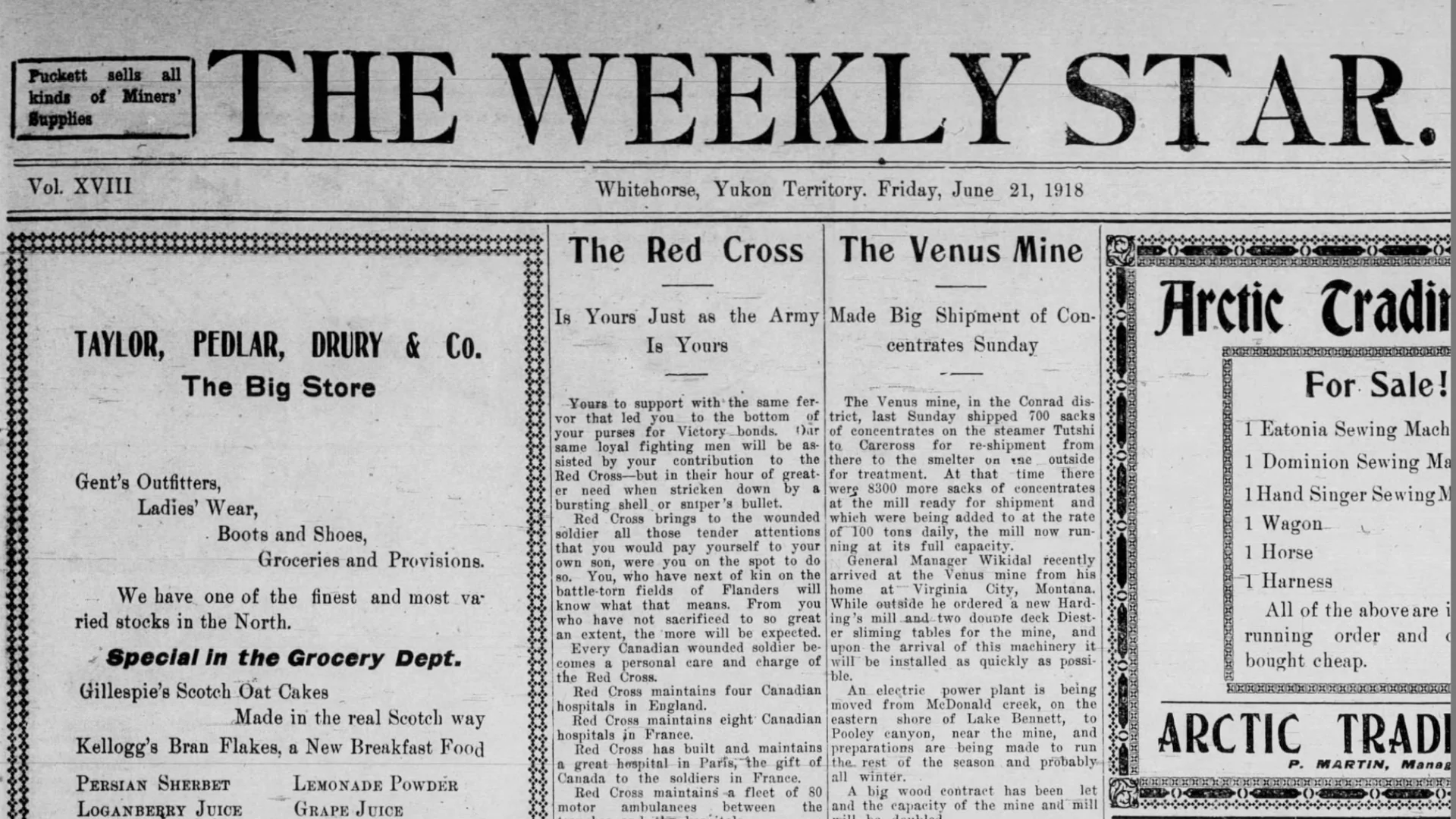

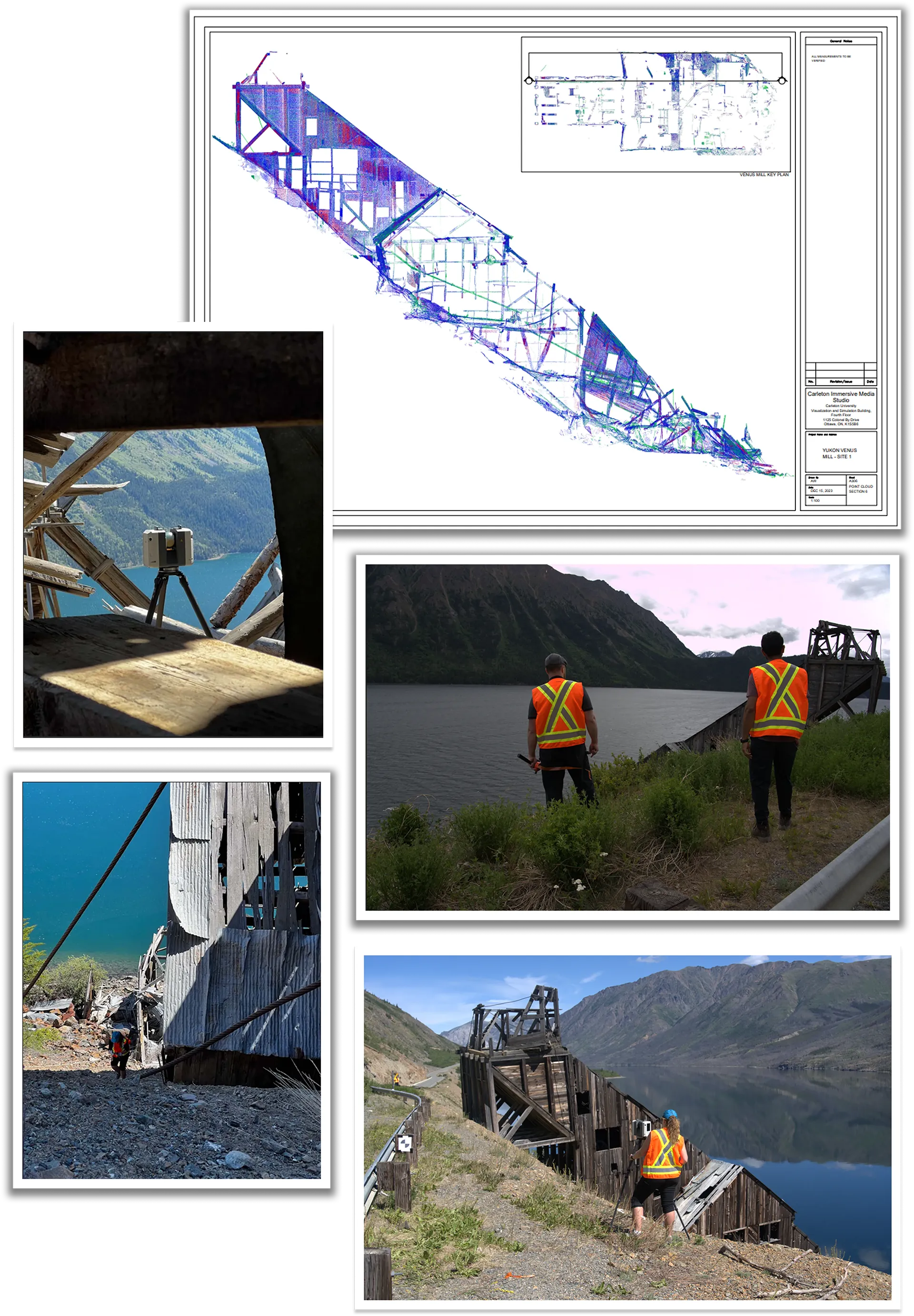

Crushing

Crushing renders rough ore into smaller, same-sized pieces. The Blake-style jaw crusher was the first step for all ore entering the mill. Later in the process, the Gates Fine Crusher, Hardinge Mill, and Huntington Mill further pulverized the smaller pieces in preparation for concentrating.

Blake Style Jaw Crusher

Sorting

Sorting is essential so that big pieces can be crushed smaller, and small pieces can be sent to the concentration stage. Crushing everything to the same size requires sorting, re-crushing, and sorting again, throughout the levels of the mill. Grizzlies (evenly spaced parallel bars) rotating trommels, callow cones, and callow screens were all used to sort finer particles from rougher pieces.

Rotating Screen / Trommel

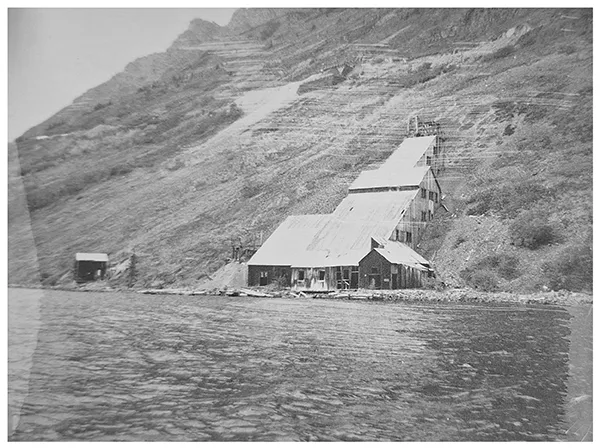

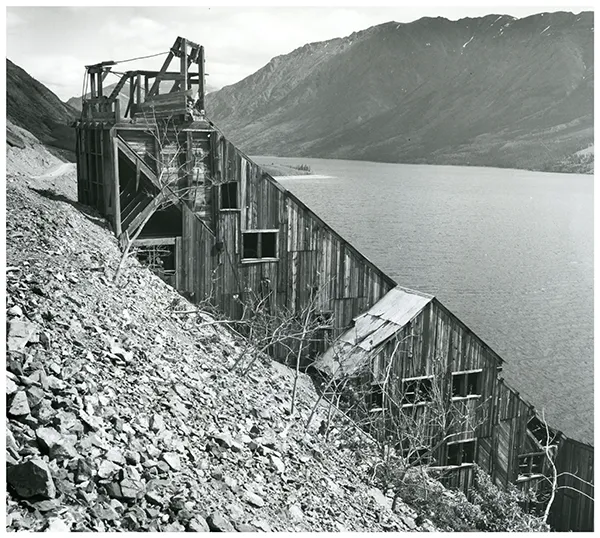

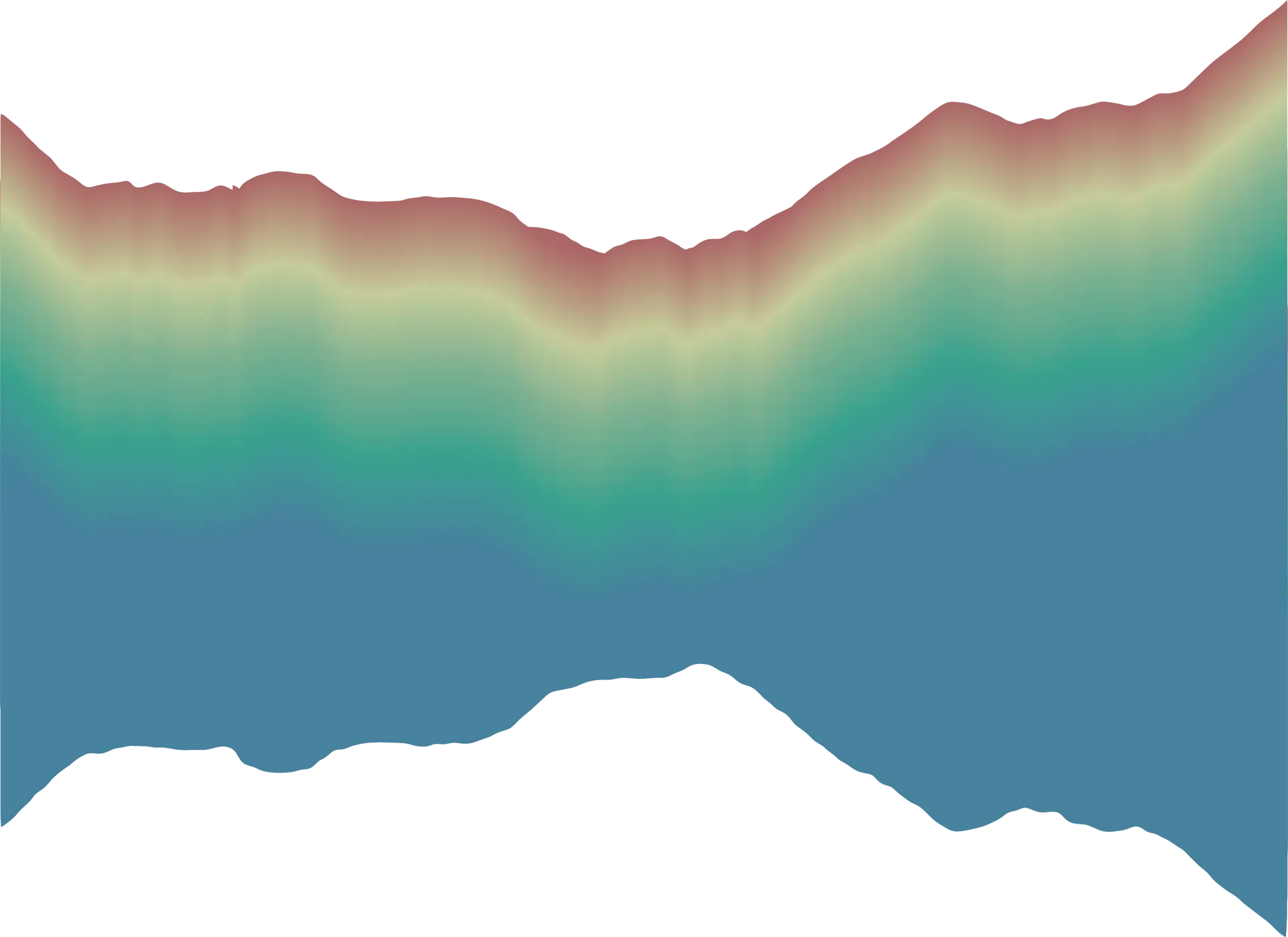

Concentrating

Concentration chemically and mechanically separates the valuable minerals from the ore to create mineral concentrate. This stage presented challenges at Venus Mill. Oil flotation tanks, Wifley tables, Frue vanners, and Deister sliming tables were installed over the years. In 1916, the mill reported heavy losses in the slimes, because the ore contained brittle and oxidized minerals. The oil flotation plant was installed in 1917, and the Deister sliming table in 1918. There were plans to install a cyanide plant in 1920, but it never happened. By whichever method, the resulting concentrate was dried and bagged for shipment. It was sent by boat to Carcross, and from there to smelters in Anyox and Trail, British Columbia.

Although the mill was intended to process all ore into concentrate, in June 1917 the high grade ore was still being sacked for shipment, and only low grade ore was being processed into concentrate at Venus Mill. Shipping large amounts of unprocessed ore was much more expensive than shipping smaller amounts of concentrate: this is evidence that the mill couldn’t reliably concentrate the higher-grade ore. Despite these challenges, at peak production the mill produced 10 tons of silver ore concentrate per day.

Flotation Tank

Support Systems

Crushing, sorting, and concentrating were the main functions of the mill – but lots of other equipment was needed for these to happen. A wood-powered steam boiler powered the equipment and generated electricity for lighting. Steam heat kept the mill warm enough to operate during the cold winter months. Compressed air supplied air to the oil flotation tanks, and may have supplied air to pneumatic devices in the mine above the mill. Water was piped in from the lake to mix with the ore during milling and flotation. Tanks and bins collected material, while chutes and landers (box conduits for ore slurry) moved materials from one location to the next.

Boiler / Steam Engine